1. CABLE: Provide a cable of applicable ampacity, service and temperature rating suitable for the conditions of use and location. The plugs and connectors are designed for use with 3, 4, or 5 conductor cables with a diameter from .375’’ to 1.156’’ (12/3 SJ through 8/5 S). 2. CORD CLAMP PREP: Gray colored cord clamp inserts preinstalled for use with .550’’ to .875’’ cable diameter. For other sizes:

A. Loosen and remove the cord clamp assembly from the housing.

B. Remove the gray colored cord clamps from the cord clamp assembly.

C. Replace with an appropriately supplied cord clamp insert:

| Black Colored Cord Clamp Insert | .375" to .550" diameter |

| Gray Colored Cord Clamp Insert | .550" to .875'' diameter |

| Red Colored Cord Clamp Insert | 750" to 1.06" diameter |

| Without Cord Clamp Insert | 1.06" to 1.156" diameter |

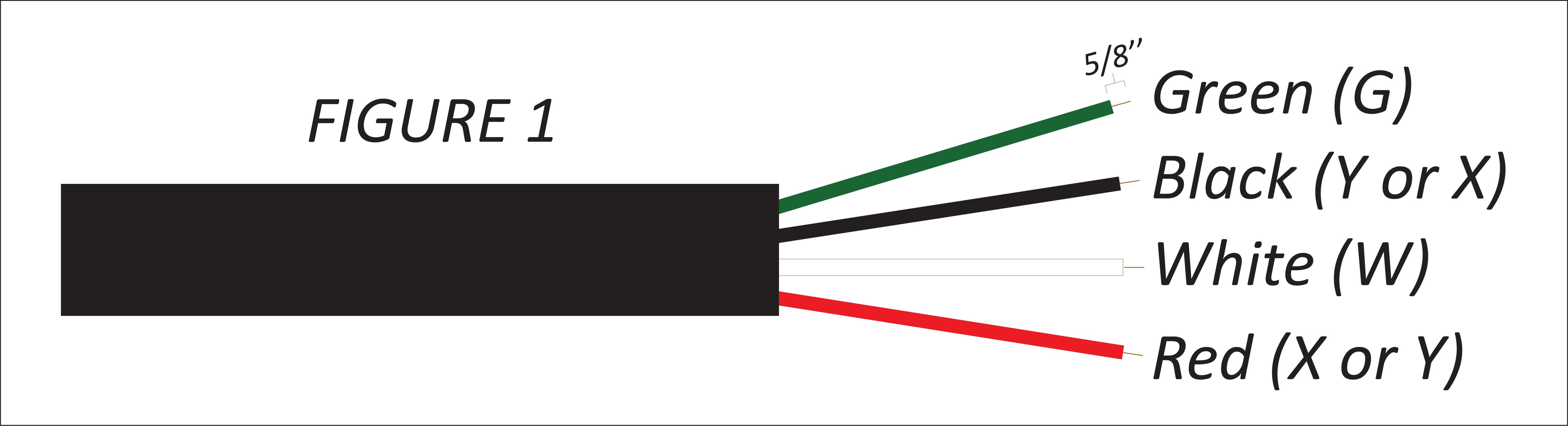

3. CABLE PREP: Remove outer jacket 2’’ and strip each individual conductor 5/8’’ as shown in Figure 1 below. Make sure the wire is clean and bright copper color. Do not solder the ends of the wire. Feed the cable end through the housing.

4. ASSEMBLY: Select the proper plug or connector for your application. Loosen the screws from the face and remove the assembly from the outer body.

FOR DEVICES WITH A W TERMINAL: Insert the green wire into the terminal with the green colored screw. (G) Insert the white wire into the terminal with the silver colored screw. (W) Insert the remaining wires (white, red, black, etc.) into the terminals marked X, Y or Z.

FOR DEVICES WITHOUT A W TERMINAL: Insert the green wire into the terminal with the green colored screw. (G) Insert the remaining wires (white, red, black etc.) into the terminals marked X, Y or Z.

When making connections, make certain they are secure, properly insulated and there are no stray wire strands outside the terminals. Tighten the terminal screws to 12-16 in-lb torque. Assemble the housing over the device body; the keyway in the housing and the body properly aligns the two parts. Tighten the cord clamp assembly screws to a maximum 10-12 in-lbs torque. Lastly, Tighten the assembly screws.

FIGURE TWO

DOWNLOAD THE USER MANUAL

Share:

User Manual: 30 Amp Inlet Box

Download: Residential Product Sheet